Adapted from my 2018 Ignite Talk

For most people in the tech world, life can be fairly drab They sit in cubicles, at insurance companies, writing code, designing their millionth, mind numbing button, or making cold calls to hostile schmucks all day. It’s a job right? Something you have to be paid to do, because no one in their right mind would do this for free.

On the other hand, we have the guys in Silicone Valley, wrapped in hoodies and self righteousness, planning on getting rich and changing the world (not necessarily in that order). But how do you get from cubicle to your dream? Working on what you love?

I would like to tell you about one the best dumb ideas of recent history: The StartupBus. A Navy Seal boot-camp training program for tech entrepreneurs. Or so I like to think.

In 2010, my friend Elias, was working in Venture Capital, and wanted to get a bus with a bunch of friends and go to South by South West – the huge film, music and tech conference in Austin. He thought would be funny to semi-mock Startup Culture in Silicon Valley by having everyone on the bus try and build a tech startup in the three days it would take to get there from San Francisco.

It sounded crazy to everyone, but they all had so much fun, that a group of them decided to turn it into a “my-city-is-better-than-your-city” tournament the following year. They all went back to their respective states, and started recruiting riders for a full-blown competition.

The format is simple: 30 strangers get selected to get on a bus, as long as they are extremely competent and fall into one of three clichéd categories: Hipsters Hackers, and Hustlers: Graphic designers, Computer programmers, and Marketing and Business Development people.

They then get on the bus day one, introduce themselves, and pitch an idea for a startup. Groups then form around the ideas, and then the teams work like crazy, for three or four days, to make an actual business. With REAL products, and even Customers – In three days!

I was first invited to ride the 2011 Miami bus. I worked on two separate teams, competed against 10 other busses, 60 other teams, and didn’t sleep for four days, and met some of the most amazing people that are still in my life to this day.

Since then, the competition has grown. There are more and more busses every year from more cities, a separate European competition, and I’ve recently gotten back from the inaugural StartupBus Africa trip, which was epic! But why would anyone do this?

Well, most people are just… terrible at their jobs. I assume you’ve found this yourself. But the bus is different. The sheer caliber of the people you meet if off the charts. Everyone works so hard, and is so good at what they do, that there is a feedback loop of inspiration; You WANT to work harder to show that you belong.

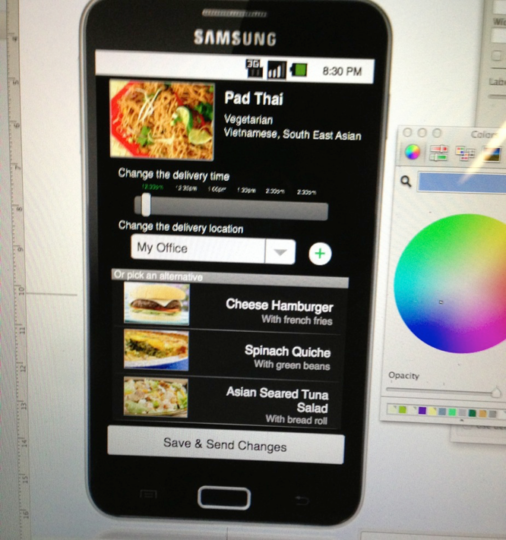

The result is productivity to an extent not seen in the real world. What can you create on a bus in three days? How about a fully fledged, artificial intelligence food ordering system that will automatically order you lunch every day? Yeah, we did that.

Internet free chat system for disaster areas? Yup. A career matching system for Veterans? Check. Customized cereal delivered to your door? Yup. A full social network for selling what you grow in your back garden – a team from Tampa built that!

And there are hundreds of others. But the bus isn’t all flowers and roses. In fact it is totally awful. And that is one of the reasons it’s so successful. If you can build something amazing in three days next to a chemical toilet, you can do anything.

There is bad food, motion sickness, team melt downs, spotty power and internet access, and every new hell you’d find in a real startup, but compressed into the equivalent of a long weekend. As a result, you learn to be flexible, to deal with the chaos, and to thrive.

Then there is the physical side. Try having a normal conversation after writing code for ten hours doing this. Also, after four days without sleep, you can have some pretty inspiring insights, as well as some mind-blowing hallucinations. Not to mention all the caffeine and alcohol.

The pure squalor of the situation, combined with the amazing team work that goes on, binds you so closely to those people, that you instantly have 30 new best friends. I started referring to the processes as entrepreneurial Stockholm Syndrome.

But the process opens your eyes. A passionate, five person team, working 16 hour days, for four days straight, produce 320 hours of actual work. That’s an equivalent 40 work days of super productivity.

If you can build a complete product, create marketing materials, pitch decks, business cards, have customers and sales, etc., all in three days, ON A BUS, what could you do if you gave yourself six months?

I bet that you’re pretty amazing. You just can’t begin to realize how freaking amazing you REALLY ARE until you’ve HAD be amazing waste deep in crap and sleep depravation. There are no excuses. Go and build something, right now!